Apr 16, 2022

I was so pumped to get my roof rack put on. I have a big fishing and camping trip coming up and have been dreaming about using my 2dr bronco with a camper top and now it's turned into a nightmare. Picked up the roof rack from the local dealer yesterday and took it home to install. The instructions say 8ft lbs on the bolts that hold the rack next to the windshield mounts. I had tightened them to proper spec and thought they were clicking. Instead I found that was actually the studs on the windshield snapping off. Totally disappointed.

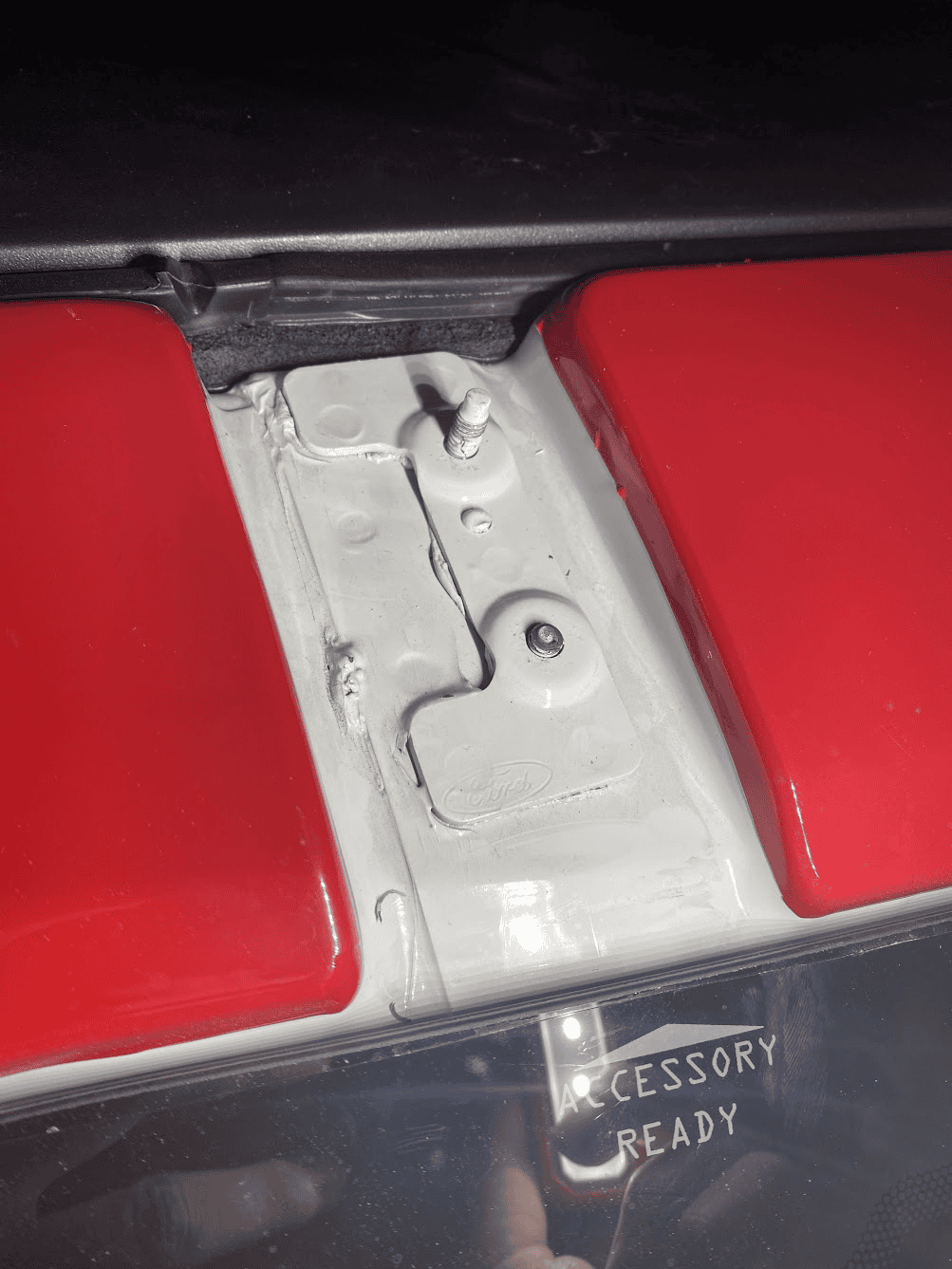

My question is, what are my options as far as having this repaired. I could weld it but don't know if I would trust it then holding a roof top tent driving down the highway. And a quick search seems like I'm not the only one. The pic below isnt mine but it's identical except I broke both. The owner of that one had to go through Ford as a warranty claim. If that's the case, I seriously doubt I'll have this repaired in two weeks for the trip

The icing on the cake is it seems the plastic is cracked on the rack itself. Not very promising as far as durability goes.

My question is, what are my options as far as having this repaired. I could weld it but don't know if I would trust it then holding a roof top tent driving down the highway. And a quick search seems like I'm not the only one. The pic below isnt mine but it's identical except I broke both. The owner of that one had to go through Ford as a warranty claim. If that's the case, I seriously doubt I'll have this repaired in two weeks for the trip

The icing on the cake is it seems the plastic is cracked on the rack itself. Not very promising as far as durability goes.

the poacher, Mal

Last edited by a moderator:

Apr 16, 2022