Jan 06, 2023

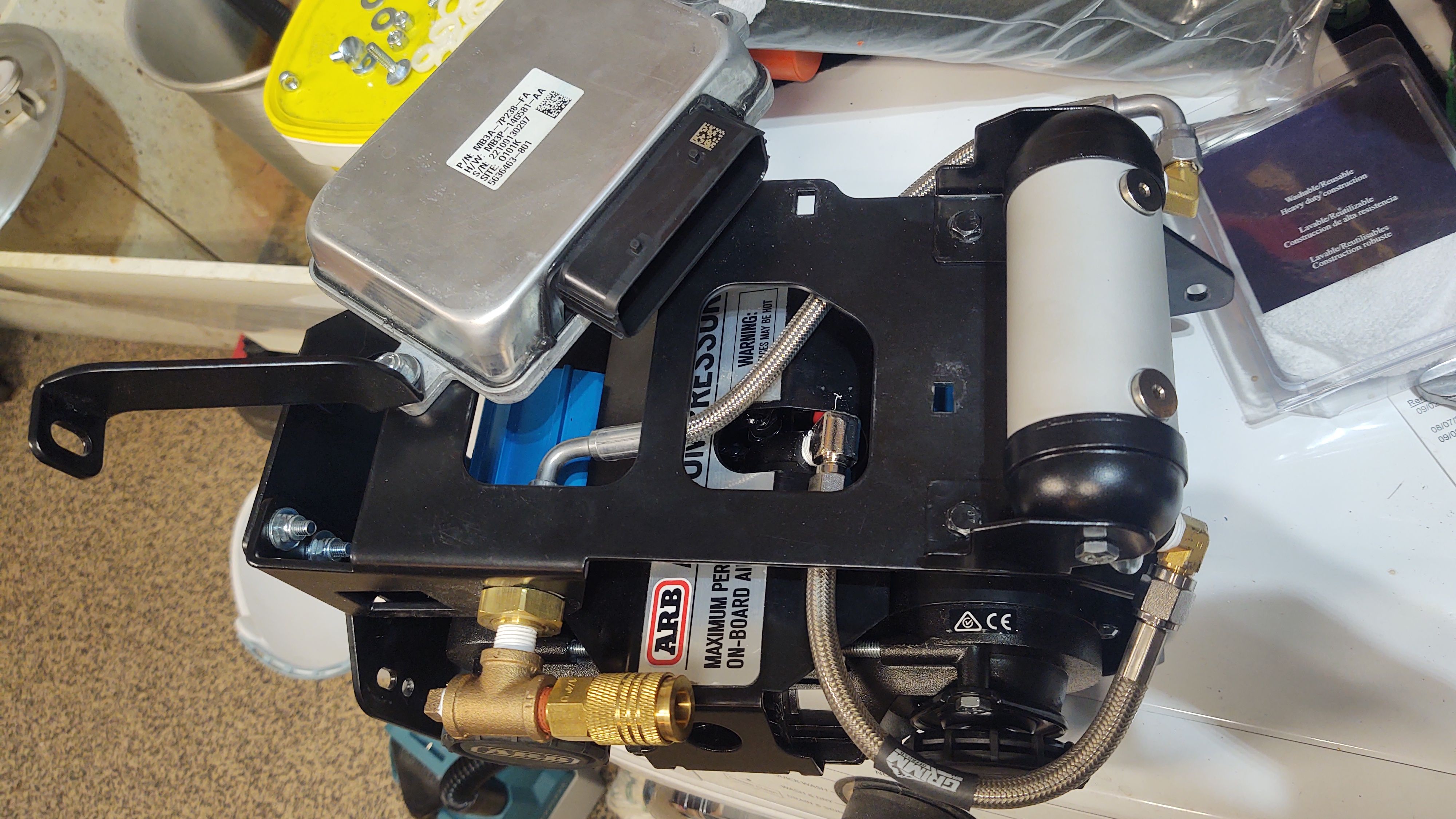

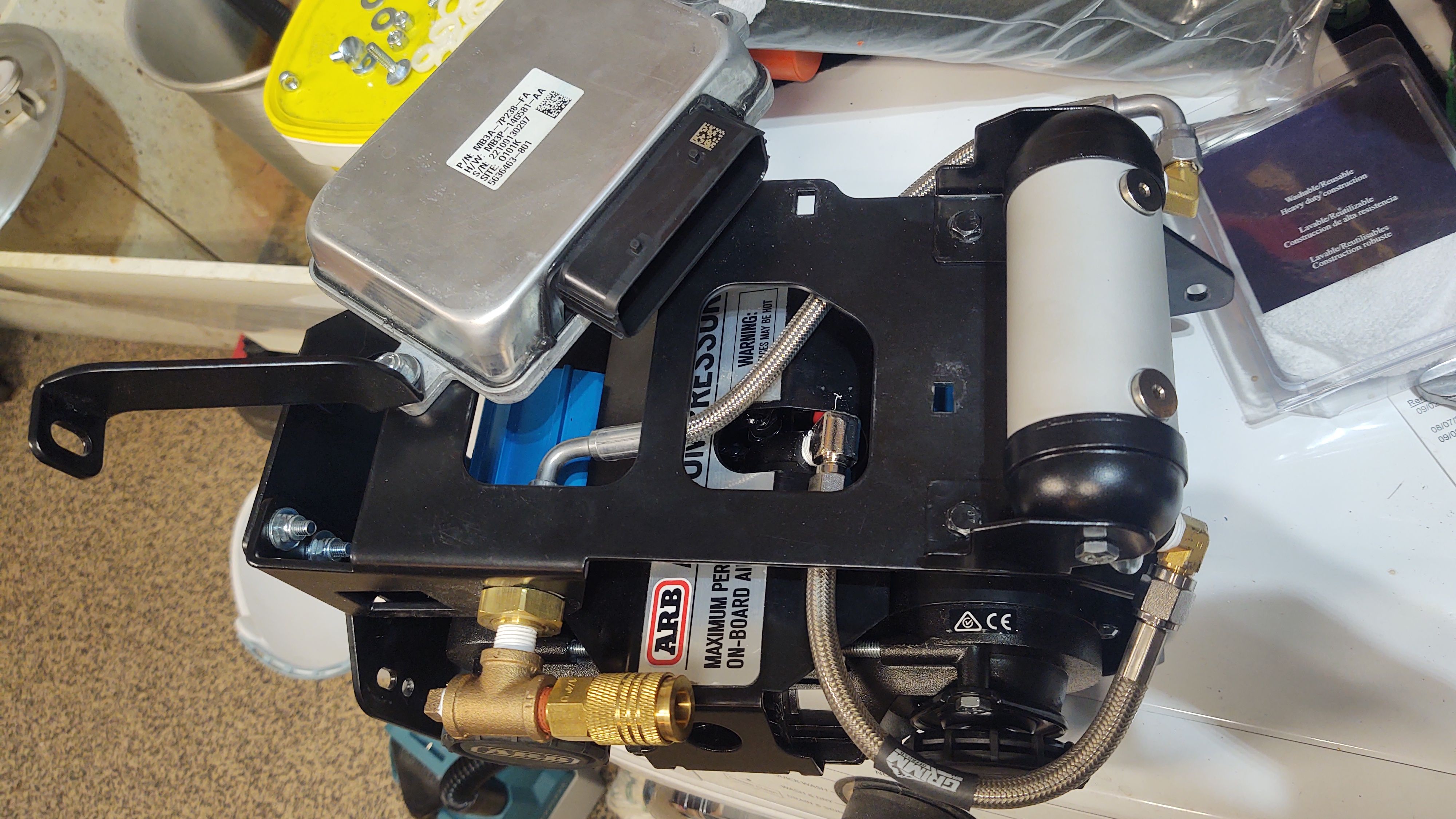

The Grimm Mount installs the compressor in the area where the PCM computer is located. It's a good kit that comes with pretty much everything you need. https://www.northridge4x4.com/part/10387-grimm-offroad-arb-twin-compressor-mounting-bracket-kit IMO its too expensive for what it is, but since ARB enforces MAP pricing on their retailers, you could probably save quite a bit with a bundle. (Or get the mount on sale). I got the compressor used on ebay for a decent price. But, it didn't come with any accessories. The Grimm website has instructions so I'm not going to bother with those details.

I also picked up two additional ARB components;

70-100PSI replacement switch ARB part #CO35SP

https://www.summitracing.com/parts/arb-co35sp (this lowers the cutoff pressure from 150PSI to 100. 150 seems silly for a tankless system intended (in my application) just to air up tires.

ARB Manifold Kit - I added this because compressed air gets extremely hot and I felt it would be good to have an additional way to dissipate some of the heat before it melts a fitting or something, but also have a little (tiny) bit of an air tank.

https://www.summitracing.com/parts/arb-171503

Since the compressor I got from ebay only came with the compressor and no wiring harness or hoses, the manifold kit was also useful for providing a braided hot line and 1 (of 3) 1/4" flare to NPT elbow fittings required. I also went to the local hardware store and picked up a brass NPT-NPT nipple, Tee, quick connect, and plug cap (for future expansion).

I considered chopping off the weird electrical connector on the ARB pump and using some anderson power pole or something similar as a replacement, but I figured out instead how I could make the mating end for my wire harness.

https://www.amazon.com/dp/B07P2CSY6P This is what you need to make a custom vehicle-end wire harness for ARB compressors (APTIV Metri-Pack 280 Series 5-Conductor 30Amp Connector)

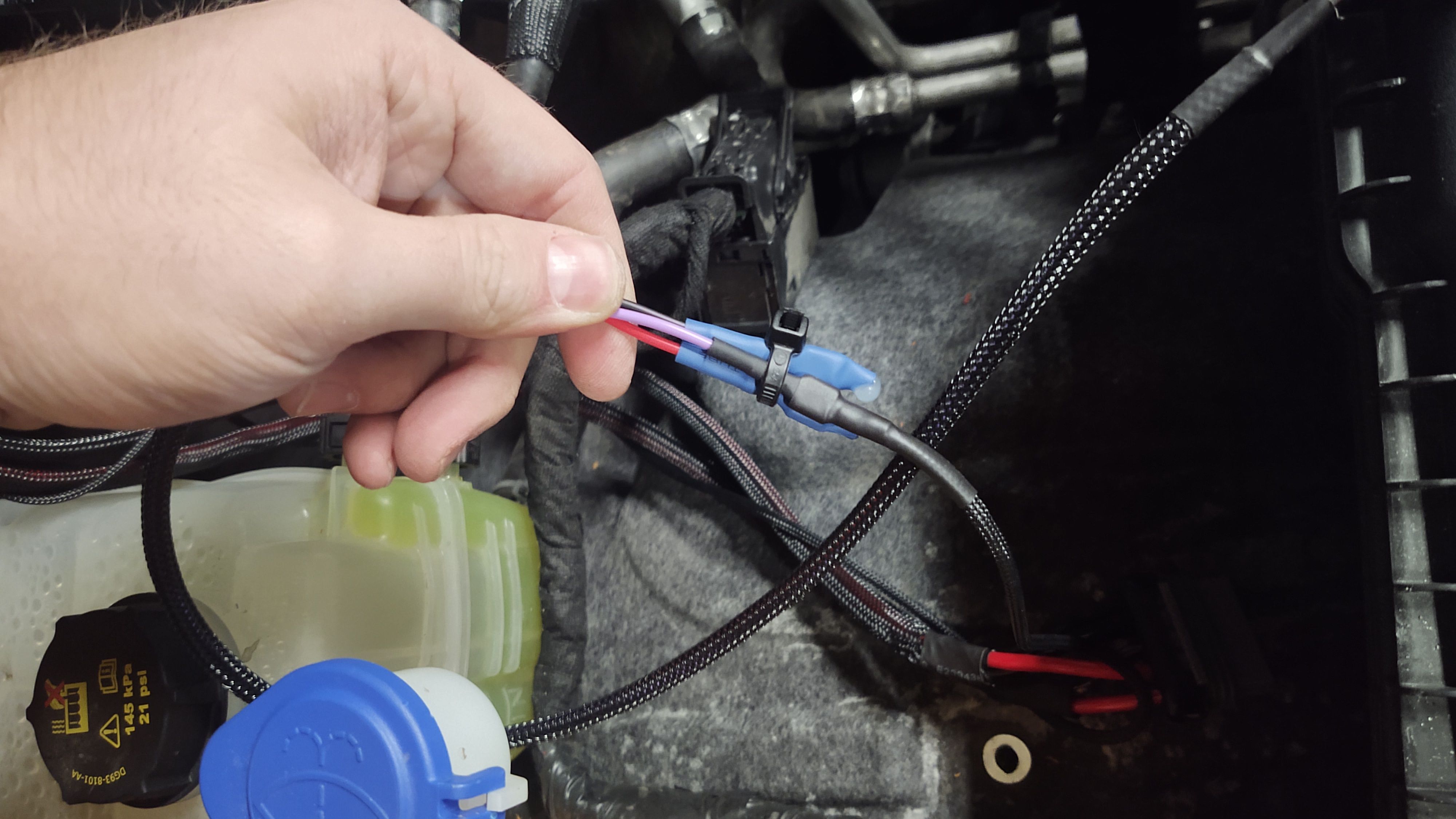

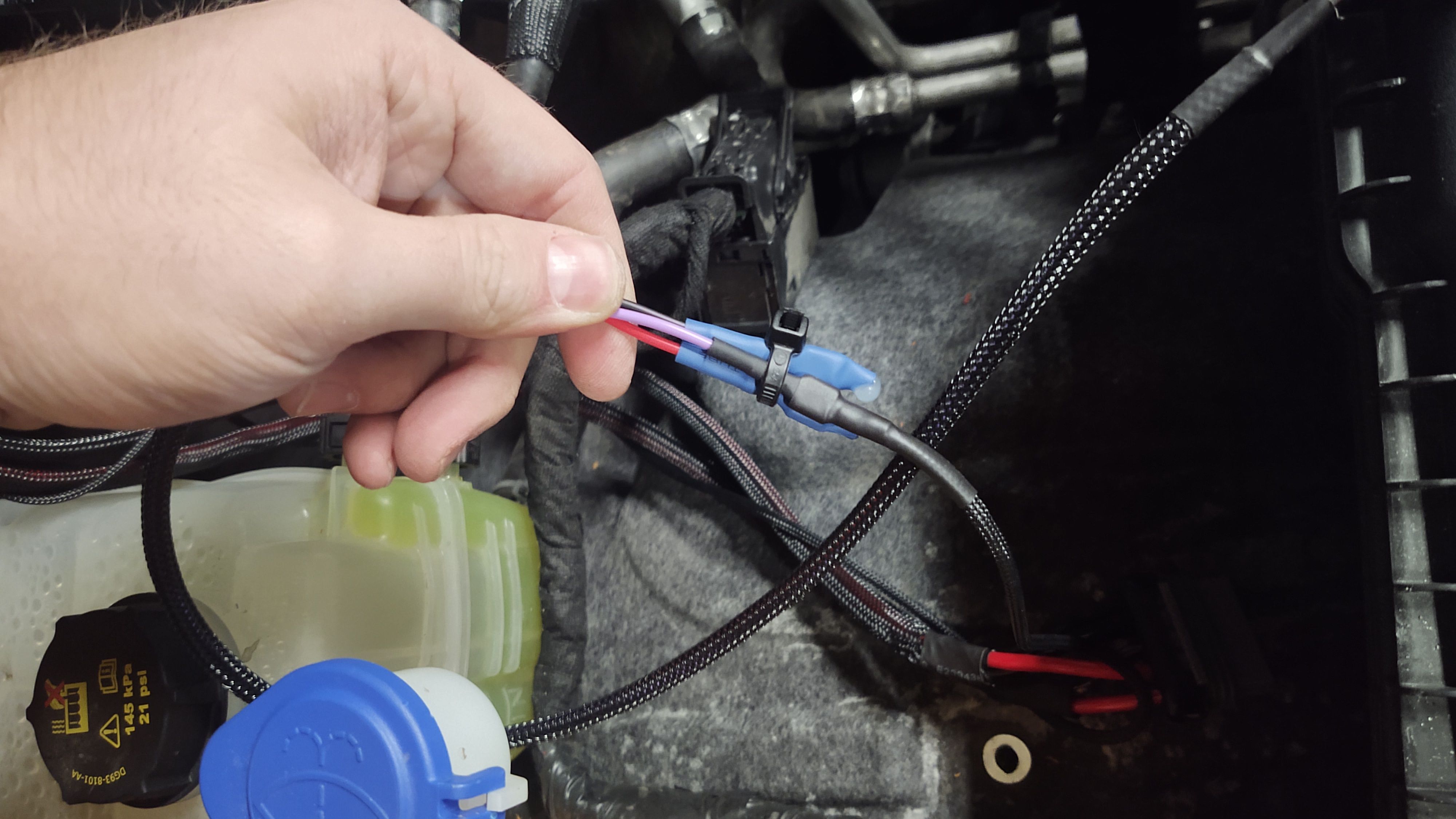

https://www.amazon.com/dp/B07BTT8G6W (You should also get a crimp jaw if you can. This *barely* worked though. I'm using AWG10 wire, and this is for AWG12, but it worked.) I ran two 10AWG ground wires and two 10AWG +12v wires to the battery, and fused them with 40A inline fuses. There is one additional ground from the wire harness on the pump with a much smaller gauge wire you need to also connect to ground somewhere. I just ran all 5 back to the battery.

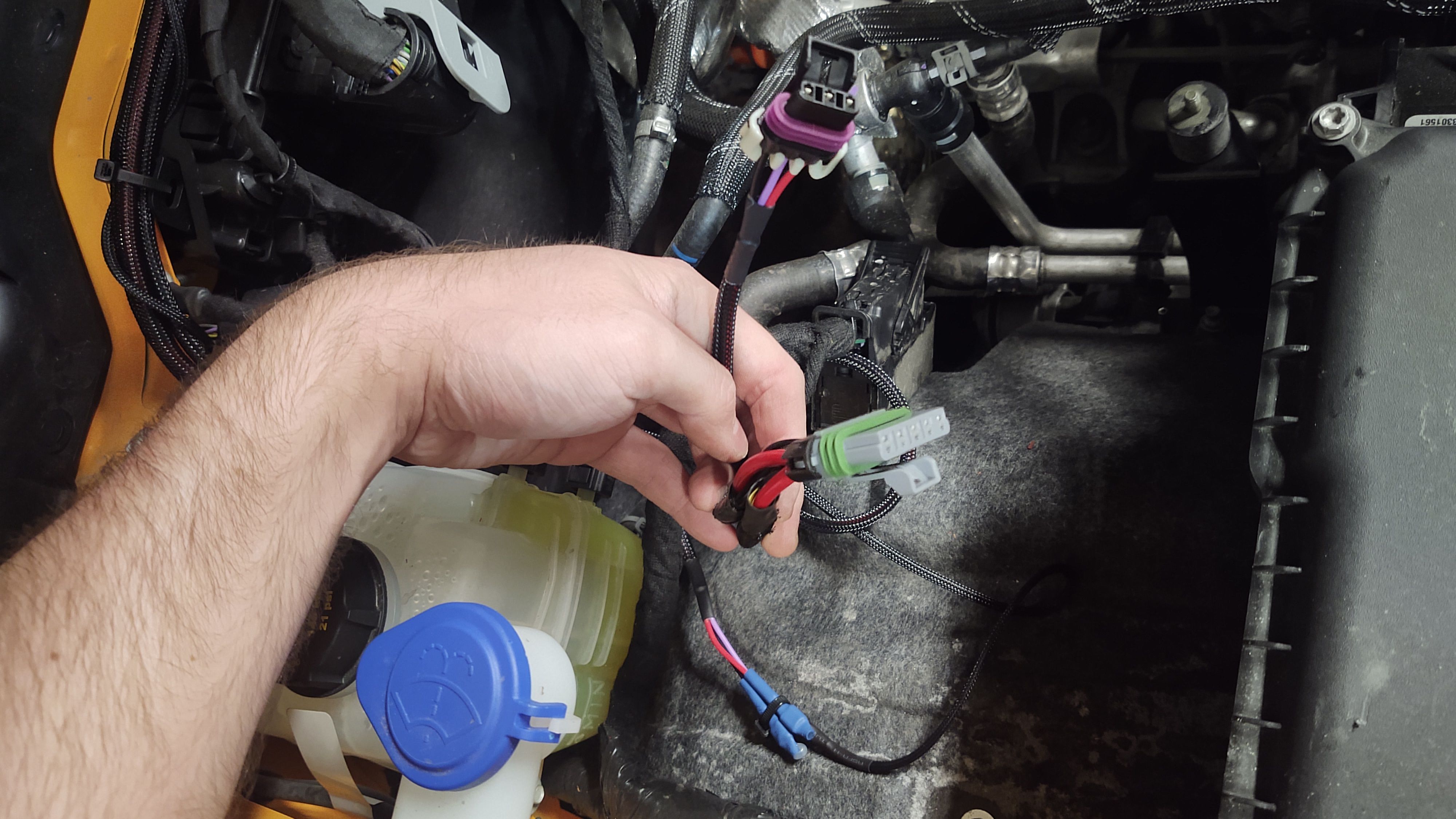

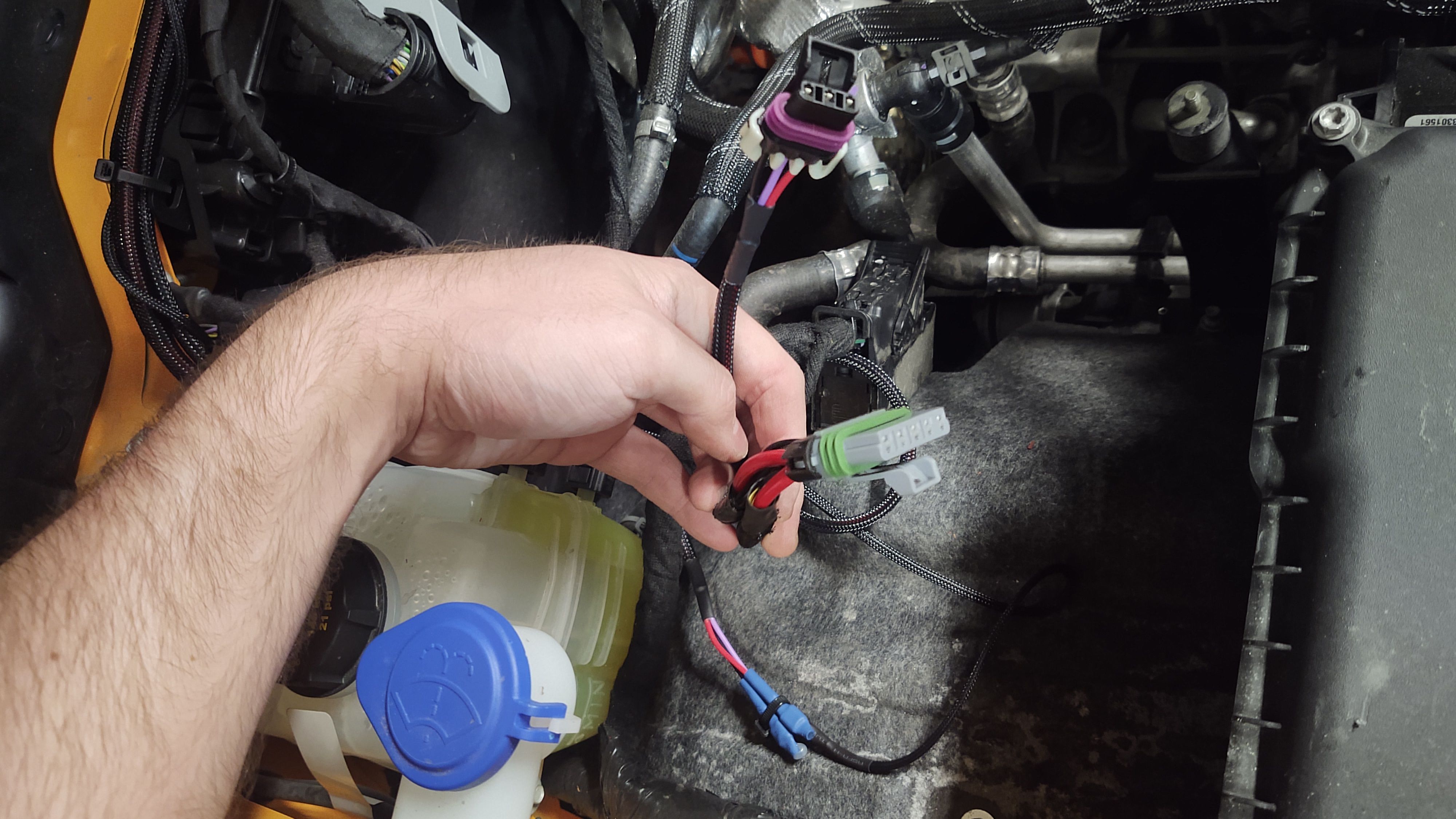

The Grimm kit comes with the 3-wire switch connector which was awesome (shown with the purple gasket). However, after some experimentation and magic smoke loss in some alligator clips, I determined that you only need to supply 12V to the PURPLE wire. The Red and Black are a +12 and Ground wire which are used to illuminate the special ARB on/off switch which I didn't have (and wasn't going to use if I did anyway) and return voltage to the relays in the pump to actually turn it on or off.

Since I'm using the Bronco's built in AUX switch wiring, I just heat-shrink and hot glue sealed the 2 unused spade connectors on the Grimm harness and connected my AUX4 BROWN wire to the purple wire. Plug that in to the compressor and that's it.

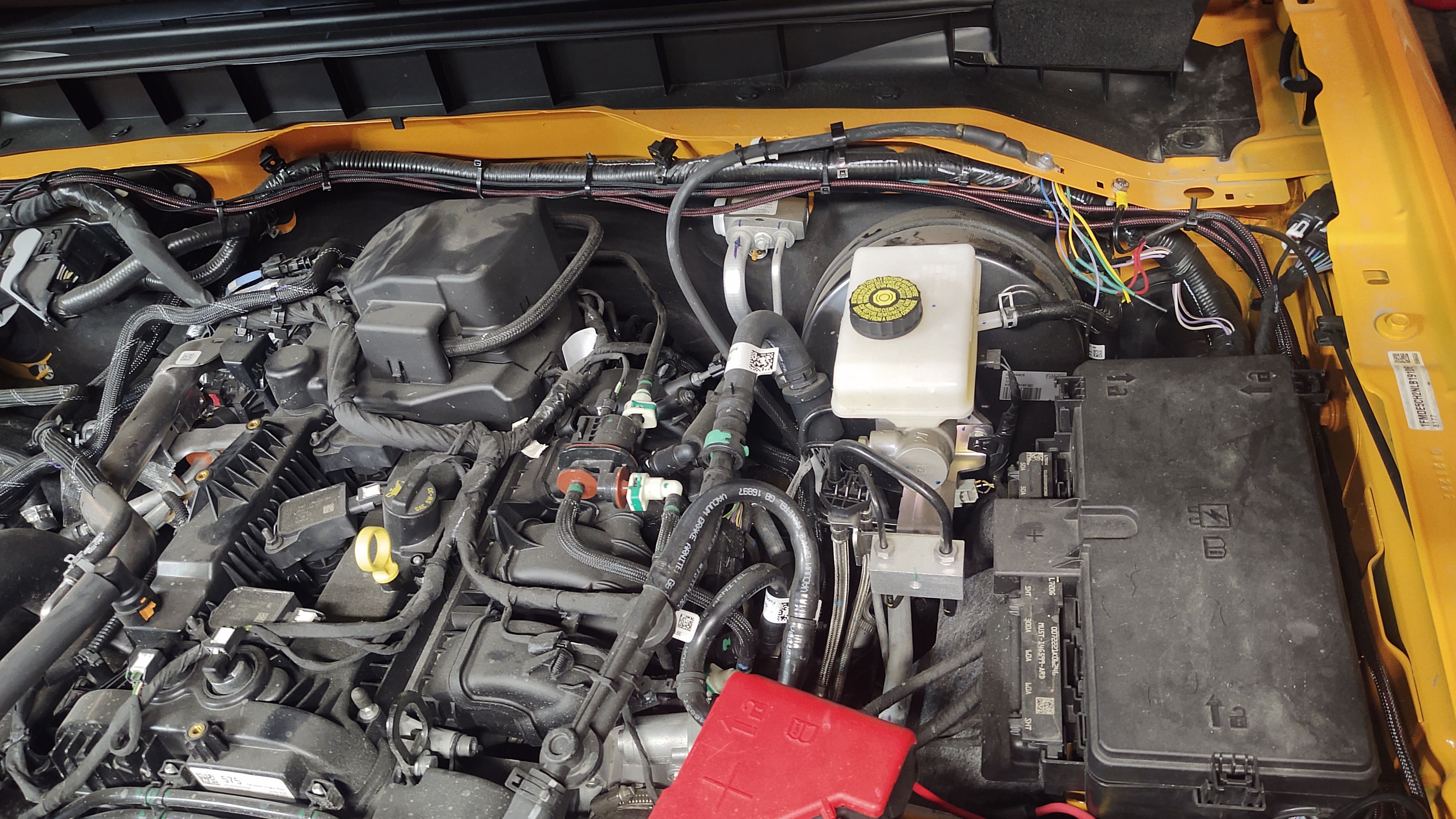

A note on wiring. ARB's power wiring on the pump is all 10 gauge stuff. Their spec sheet says maximum current draw for the pump is around 70Amps or something. Split across two separate wires, that means about 35 amps of current peak is needed to be carried. Their choice of 10 gauge is great for super short runs, but they really should have used 8 gauge to make mounting locations a bit more flexible, in my opinion. Unless you want to deal with high resistance and voltage drop which can lead to overheating, keep your power wire runs as short as you can. I stuck with 10 gauge wiring because I'm in the engine bay and all told the power run is pretty short. Any more distant though and I'd have to consider much larger wires.

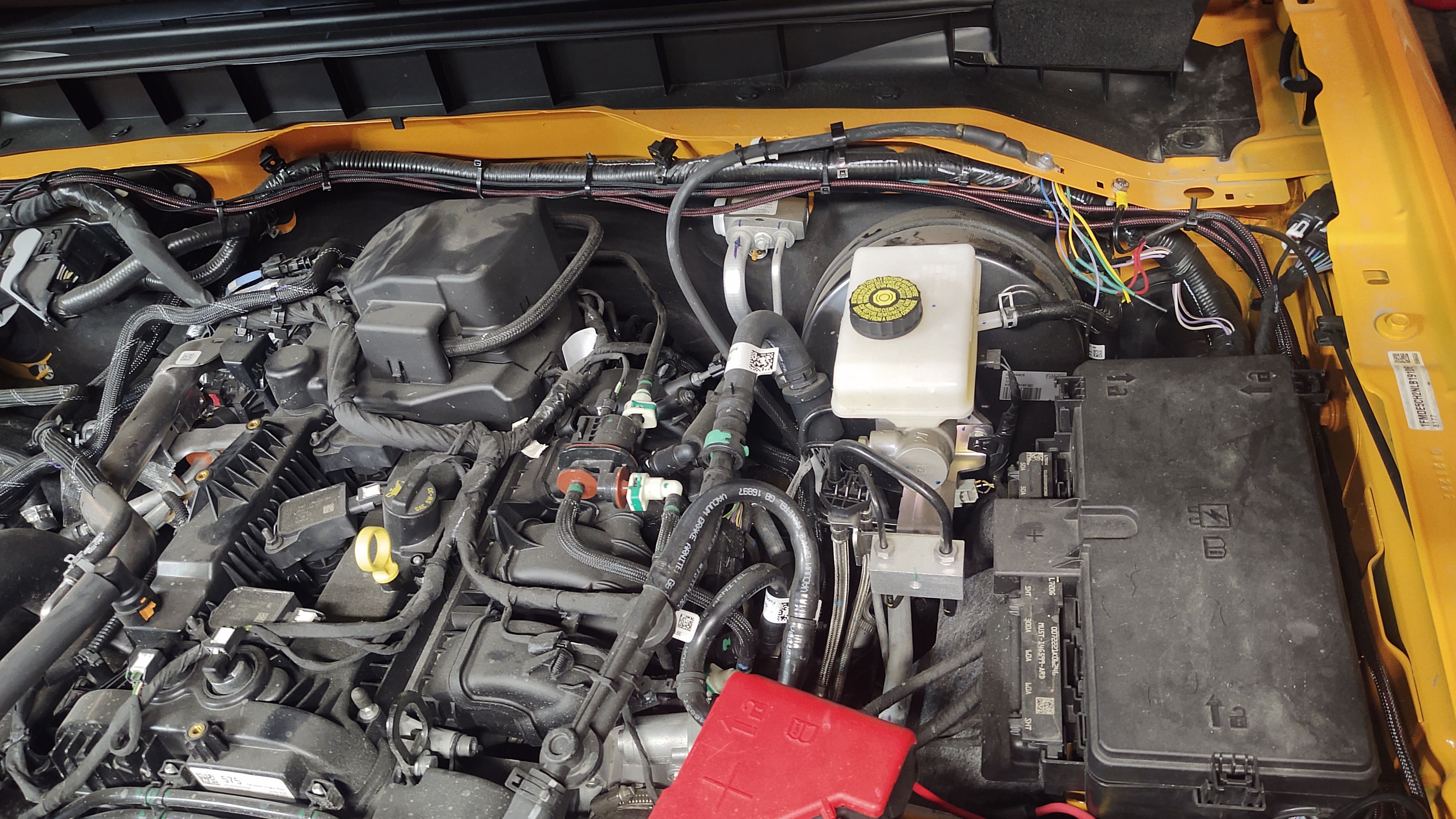

I used 1/4" expandable cable braiding (beautiful stuff) and heat shrink tube to make 3 protected wire looms to run to the pump. I followed the Bronco's existing wire harness along the top most edge of the engine bay, and split off loom 3 to my upfitter switch wiring area. I added a piece of plastic wire wrap and fit loom 1 and 2 along side the power distribution box and then out where the battery is.

Loom 1: +12v / Power Ground

Loom 2: + 12v / Power Ground / Control Ground

Loom 3: +12v upfitter wire (AWG 16, extremely low current requirement)

Looms 1 and 2 combine pump side on the APTIV/Delphi connector. Loom 3 connects to the Grimm connector purple wire.

That's pretty much it.

Eventually, I'm going to plumb some air line into the cabin and put air chucks on either side where the doors are so airing up doesn't require opening the hood. But for now, this is fine. I ran an experiment and it took a 35" sasquatch tire from 19psi to 42psi in about 2.5 minutes. Not too shabby.

I also picked up two additional ARB components;

70-100PSI replacement switch ARB part #CO35SP

https://www.summitracing.com/parts/arb-co35sp (this lowers the cutoff pressure from 150PSI to 100. 150 seems silly for a tankless system intended (in my application) just to air up tires.

ARB Manifold Kit - I added this because compressed air gets extremely hot and I felt it would be good to have an additional way to dissipate some of the heat before it melts a fitting or something, but also have a little (tiny) bit of an air tank.

https://www.summitracing.com/parts/arb-171503

Since the compressor I got from ebay only came with the compressor and no wiring harness or hoses, the manifold kit was also useful for providing a braided hot line and 1 (of 3) 1/4" flare to NPT elbow fittings required. I also went to the local hardware store and picked up a brass NPT-NPT nipple, Tee, quick connect, and plug cap (for future expansion).

I considered chopping off the weird electrical connector on the ARB pump and using some anderson power pole or something similar as a replacement, but I figured out instead how I could make the mating end for my wire harness.

https://www.amazon.com/dp/B07P2CSY6P This is what you need to make a custom vehicle-end wire harness for ARB compressors (APTIV Metri-Pack 280 Series 5-Conductor 30Amp Connector)

https://www.amazon.com/dp/B07BTT8G6W (You should also get a crimp jaw if you can. This *barely* worked though. I'm using AWG10 wire, and this is for AWG12, but it worked.) I ran two 10AWG ground wires and two 10AWG +12v wires to the battery, and fused them with 40A inline fuses. There is one additional ground from the wire harness on the pump with a much smaller gauge wire you need to also connect to ground somewhere. I just ran all 5 back to the battery.

The Grimm kit comes with the 3-wire switch connector which was awesome (shown with the purple gasket). However, after some experimentation and magic smoke loss in some alligator clips, I determined that you only need to supply 12V to the PURPLE wire. The Red and Black are a +12 and Ground wire which are used to illuminate the special ARB on/off switch which I didn't have (and wasn't going to use if I did anyway) and return voltage to the relays in the pump to actually turn it on or off.

Since I'm using the Bronco's built in AUX switch wiring, I just heat-shrink and hot glue sealed the 2 unused spade connectors on the Grimm harness and connected my AUX4 BROWN wire to the purple wire. Plug that in to the compressor and that's it.

A note on wiring. ARB's power wiring on the pump is all 10 gauge stuff. Their spec sheet says maximum current draw for the pump is around 70Amps or something. Split across two separate wires, that means about 35 amps of current peak is needed to be carried. Their choice of 10 gauge is great for super short runs, but they really should have used 8 gauge to make mounting locations a bit more flexible, in my opinion. Unless you want to deal with high resistance and voltage drop which can lead to overheating, keep your power wire runs as short as you can. I stuck with 10 gauge wiring because I'm in the engine bay and all told the power run is pretty short. Any more distant though and I'd have to consider much larger wires.

I used 1/4" expandable cable braiding (beautiful stuff) and heat shrink tube to make 3 protected wire looms to run to the pump. I followed the Bronco's existing wire harness along the top most edge of the engine bay, and split off loom 3 to my upfitter switch wiring area. I added a piece of plastic wire wrap and fit loom 1 and 2 along side the power distribution box and then out where the battery is.

Loom 1: +12v / Power Ground

Loom 2: + 12v / Power Ground / Control Ground

Loom 3: +12v upfitter wire (AWG 16, extremely low current requirement)

Looms 1 and 2 combine pump side on the APTIV/Delphi connector. Loom 3 connects to the Grimm connector purple wire.

That's pretty much it.

Eventually, I'm going to plumb some air line into the cabin and put air chucks on either side where the doors are so airing up doesn't require opening the hood. But for now, this is fine. I ran an experiment and it took a 35" sasquatch tire from 19psi to 42psi in about 2.5 minutes. Not too shabby.

JR007, Function_7

Last edited by a moderator:

Jan 06, 2023